Acrylic Bathtubs vacuum forming machine by electricity or oil

- Description

- Inquiry

Description

Acrylic Bathtubs vacuum forming machine

Specification

1.The heater oven can be used by electricity or oil;

2. Used the FRP mould;

Pictures of machine parts

Main Technical Data

| Parameters | Contents |

| Material | PP, PE, PS, PVC, PET, ABS, HIPS, Acrylic degraded material, etc. |

| Sheet thickness | 2-6mm |

| Max forming area | 1700×700mm |

| Max forming depth | 650mm |

| Work efficiency | 2-3min/pcs |

| Heating oven | Electricity or Gas, depend on client’s requirement |

| Power supply | 380V/50Hz 3 phase |

| Air pressure | 0.6-0.8Mpa |

| Machine size(L×W×H) | 3000*4200*4000mm |

| Net weight | About 4000kg |

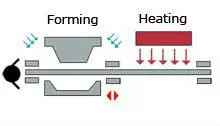

Schematic diagram

Technical Data TVF series

| Components | Description | QTY |

| Heating oven | 1.Room size:6500*3500*1100mm; 2.Liner is 201 stainless steel plates; the outer wall is cold plate; 3.Oven wall thickness:100mm, filled with insulation foam; 4.Heating:electric heat tube, the upper and lower double-sided heating; 5.Temperature: multi-sensor automatic thermostat; 6.Temperature range: room temperature to 399 degrees; 7.Power 45KW+45KW=90KW; 8.Movable blocking door can divided the oven into two parts; | 1 |

| Swimming pool forming platform | 1.The largest forming size:5900*2400mm; 2.Transmission: hydraulic; 3.Balance error:3mm; 4.Operating modes: command-style semi-automatic; 5.Transmission of plastic sheet: Directive mechanical transmission; 6.Up and down travel limit:1m; 7.Clamp method: grouping manual rapid clips; | 1 |

| Spa forming platform | 1.The largest forming size:2400*2400mm 2.Transmission: hydraulic; 3.Balance error:3mm; 4.Operating modes: command-style semi-automatic; 5.Transmission of plastic sheet: Directive mechanical transmission; 6.Up and down travel limit: 1m; 7.Clamp method: grouping manual rapid clips; | 1 |

| Vacuum pump | 100 liter rotary vane vacuum pump or water ring vacuum pump | 1 |

| Vacuum tank | 1.Volume: Recommendation 20 cubic meters, horizontal layout; 2.Maximum negative pressure: -0.9; 3.Automatic vacuum control; 4.Vacuum time:12 minutes; | 1 |

| Hydraulic system | 1.7,5P hydraulic station:1pc 2.Safety limit load: 12 tons 3.Hydraulic rod: two pieces each elevating platform; 4.Diameter of piston rod: 80mm; 5.Hydraulic weight transfer; 6.Automatic pressure maintaining , adjustable pressure; | 1 |

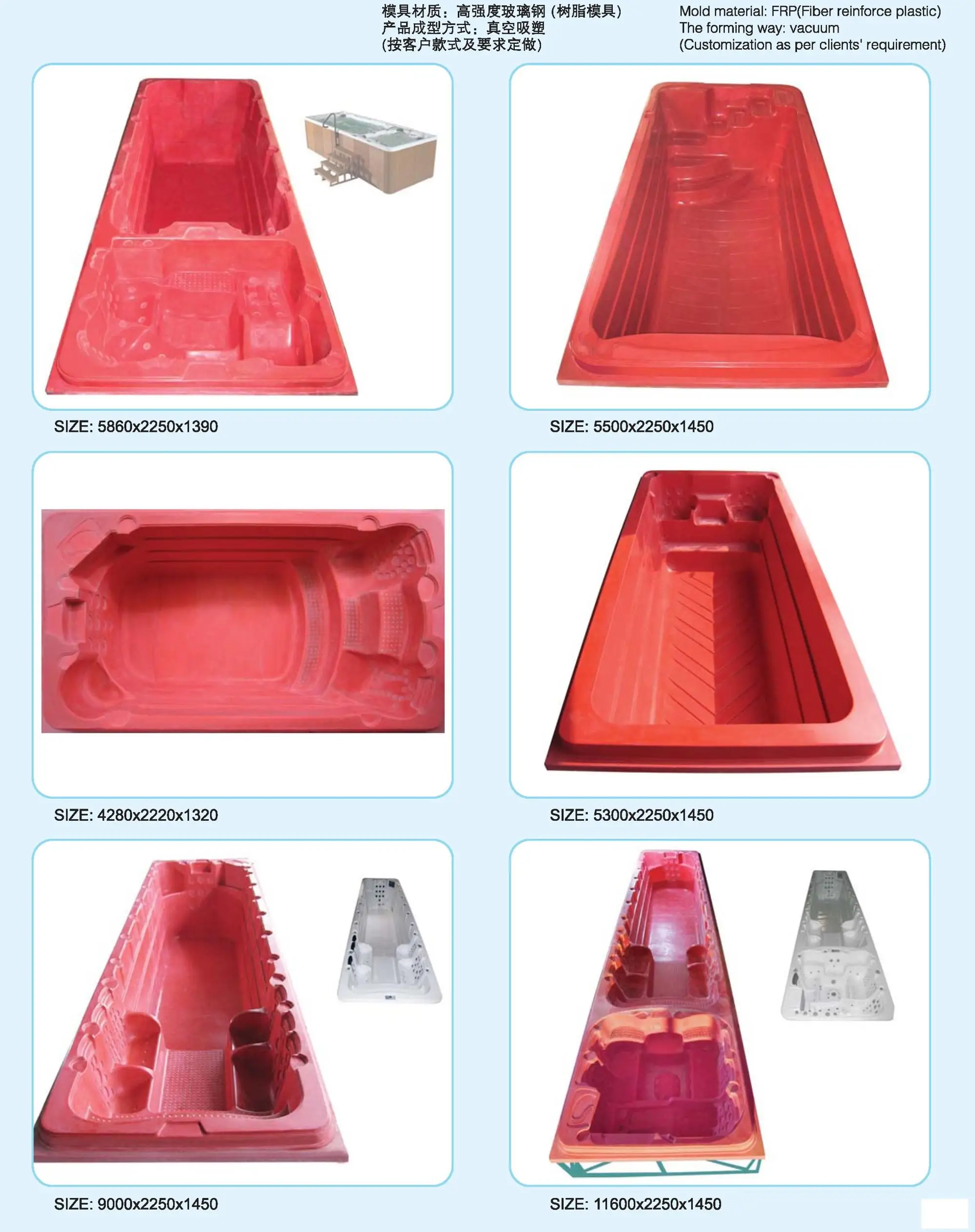

FRP mould

Auxiliary Equipments

Resin Mixer

| Name | Resin mixer |

| Size | Φ1200*2500mm |

| Motor power | 3KW |

| Heater power | 12KW |

| Volume | 1m3 |

| Weight | 860kg |

Cutting machine

Name | Size of platform | Power | Weight |

Cutting machine | 2400*2400mm | 4KW | 1300KG |

Remarks: The price is non-including the mold cost.

Payment Terms: T/T 40% deposit before production, 60% balance against b/l copy;

Delivery time: 35-40 business days after deposit;

Validity: 30 days after quote.

Departure Port: Guangzhou Huangpu port Packing: wooden block

Warranty: We guarantee these machines for one year. And we supply some spare parts with the machine,operation manual and operation CD, etc.

Service: We will send engineer who install and train in your company for approximately 7 to 10 days, after machine is arrived your place. And the flight tickets, visa and accommodation of engineer will be arranged by buyer, also the buyer need pay 50USD/day for training cost.

Because we are the manufactoy, we can design the machine as the customer’s requirement. Please send more details about your products.