Automatic High Speed Plastic vacuum thermoforming machine

plastic vacuum thermoforming machine

1)ISO9001:2008 and CE

2)easy to operate, fine workmanship

3)accurate,durable

- Description

- Inquiry

Description

Technical Data AVF2000 series

| Model | AVF-2000T | AVF-2000TA | AVF-2000TLA |

| Suitable material | PVC,HIPS,PS,PP APET,PETG | ||

| Forming width | 460-710mm | ||

| Forming length | 760-1220mm | 760-1350mm | |

| Forming height | APPOX.200mm | ||

| Vacuum pump | 2.2KW(4HP) | 3KW(5,5HP) | |

| Spray Gun | 10units | 12units | |

| Chiller System | 61000BTU | 72000BTU | |

| Temperature control | 60untis | 66untis | |

| Oven power consumption | 24KW | 26.4KW | |

| Max. power consumption | 26KW | 30KW | |

| Power Supply | 380VAC/3phase/50Hz; 220VAC/3phase/60Hz; | ||

| Machinery size(L*W*H) | 6560*1500*2700mm | 6920*1500*2700mm | |

| Weight | 3150kg | 3200kg | 3550kg |

Those models are suitable for the mass production;

Automatic High-Speed Vacuum Forming Machine

- By PLC under auto mode

- High capacity

- Environmentally friendly

♦ Vacuum forming, commonly known as vacuuming, is a simplified version of thermoforming, whereby a sheet of plastic is heated to a forming temperature, stretched onto or into a single-surface mold, and held against the mold by applying vacuum between the mold surface and the sheet. The vacuum forming process can be used to make most product packaging, speaker casings, and even car dashboards.

Feature

- By PLC under automatic mode.

2. The sheet moving by the servo motor: its speed can be adjustable, the torque is large and high precision.

3. It is reliable in thick sheets.

4. With the specially-made alloy track its friction ratio is small and it is stable and quick in drawing sheets.

5. Air channel adopts copper pipe: anti-aging protective, durability.

6.Digital display pressure regulating module control oven temperature: voltage stabilization, temperature stabilization and beautiful and graceful.

7. This machine is made of three parts, the heater part, the forming part and the cutting part.

8. The customer must offer the sample or drawing, then we can design and produce the forming mold and cutting mold.

The machine is no-including the cost of those molds.

The main component:

Electrical element: Pneumatic component:

Timer and relay: “OMRON” Japan. Cylinder: “Zhicheng” China or “Airtac” Taiwan

Inverter: “MITSUBISHI” Japan. Solenoid pilot actuated valve: “Zhicheng” or “XMC” China

AC contactor: “Schneider” France. Air treatment component:: “Zhicheng” or “XMC” China

Cold-water atomizer: “Prona” Taiwan

Auxiliary equipment or component:

Vacuum pump: “Rietschle” or”Busch” made in Germany

Industrial Chiller: “SME” China

Chain: Stainless steel

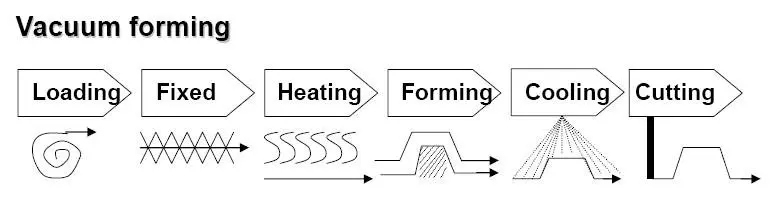

Technical process

Our service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Well-trained and experienced staffs to answer all your enquires in fluent English

3. Products: one year warranty