PE/PP single layer sheet production line/extrusion machine/making machine

- Description

- Inquiry

Description

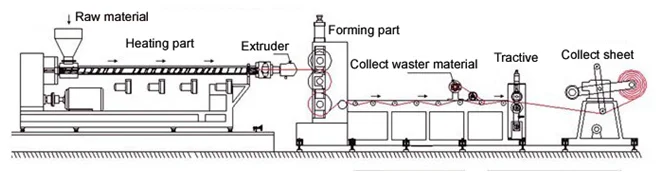

Schematic diagram

![]() Usage

Usage

EPS Series Vertical Mono-layer PP/PS Sheet Extrusion Line is specially designed to produce monolayer Polypropylene/Polystyrene/Polyethylene plastic sheet rolls, which is widely used to produce disposable plastic thermoforming items for food packaging, such as, water drinking cups, ice-cream cups, disposable cup/bowl for yoghurt, lids, dishes, plates, clamshell, food containers and etc.

![]() Features

Features

1.EPS Series Vertical Mono-layer PP/PS Sheet Extrusion Line consists of single-screw extruder(including T-die and hydraulic double-sieve screen changer), Vertical three-roller calender, Cooling bracket, Hual-off Unit, double working-position rewinder, and electric control cabinet.

2.The main parts, such as screw&barrel, screen exchanger and T-die adopt superior alloy steel with high hardness, strong corrosion resistance and long operating life after nitrogen treatment

3.Strong and durable hard-surface drive system makes sure the stable output and good quality

4.Non-stop fast screen changer with double-sieve is controlled by hydraulic unit, which ensures easy operation and high production efficiency.

5.The connection method of main motor and gear box adopts direction type, which ensures the machine stable working and high output.

6.Double working-position air-shaft rewinder ensure quick changement of sheet rolls and easy operation.

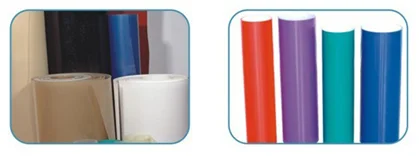

Samples

Technical Data EPS series

| Model | EPS 105/660 | EPS 110/800 | EPS 120/800 |

| Material Used | PP/GPPS&HIPS/PE | ||

| Max.Sheet Width | ≤660mm | ≤720mm | ≤720mm |

| Sheet Thickness | 0.3-2.0mm | 0.3-2.0mm | 0.3-2.0mm |

| Layer | 1 | 1 | 1 |

| Max.Extrusion Capacity | ≤200-250Kg/hr | ≤250-300Kg/hr | ≤300-350Kg/hr |

| Screw Dia. | 105mm | 110 | 120 |

| L/D Ratio | 33:1 | 33:1 | 33:1 |

| Calender Roller Dia.&Length | Ø316mm*750mm | Ø420mm*800mm | Ø420mm*800mm |

| T-die Width | 730mm | 800mm | 800mm |

| Motor Power | 55KW | 75KW | 90KW |

| Overall Power | 100KW | 130KW | 160 KW |

| Overall Dimension | 12.0*1.6*2.2 | 12.5*1.8*2.2 | 13.0*1.8*2.2 |

| Weight | 5.0T | 5.5T | 6.0T |

| Standard Power Supply | 380V/50HZ, Tri-phase, Four-wire (special voltage available) | ||

1. Payment terms:40% paid for deposit by T/T before production arranged, the balance to be paid before shipment;

2. Delivery time: 25-35 days after receipt of deposit;

3. Guarantee: One year;

We supply you spare parts for 1 year, but the freight will be on buyer’s account;

4. Installation: Our company can send one technician to the buyer’s side for machine installation, test running machine and basic training. If it exceeds one week, the buyer needs to pay US$100 one day for the technician as the salary. The visa and round trip tickets, accommodation will be on the buyer’s account;

5. Note: The above machines are designed for power supply Tri-phase, 380V/50HZ. The price of machine part will be 5% higher if we should make special design to suit for the power supply;